In the summer of 2022, the Subaru Telescope suspended observations for about two months for telescope maintenance and the aluminum recoating of the primary mirror. This was the 9th coating for the Subaru Telescope primary mirror, and it has been five years since the 8th one in 2017.

A high mirror reflectivity is essential for efficient observations. However, the reflectivity decreases over time due to the dust and dirt accumulation on the mirror surface. Before the recoating, the reflectivity of the primary mirror at 400 nanometers (violet light) was about 17 percent lower than in 2017.

The recoating process started with removing the primary mirror and the Cassegrain focus instrument from the telescope. The primary mirror was then washed with acid to remove the old coating. The surface was inspected and repaired. Then the mirror was recoated with aluminum in a vacuum chamber. Because the work is intensive and heavy-industry-scale, but at the same time requires precision, we prepared for more than one year. COVID-19 prevention measures were implemented while working at the summit. Actual summit work constituted only about 20% of the entire process; the other 80% being preparation.

Figure 1: The primary mirror just after the start (top) and near the end (bottom) of the primary washing. The old aluminum coating was dissolved during the washing, and the actuator holes can be seen through the large transparent glass. The supports in the actuator holes in the bottom photo are not the real actuators. The high resolution image is here (1.1 MB). (Credit: NAOJ)

Mirror Washing

The primary mirror was washed twice. In the primary washing, hydrochloric acid dissolved the old aluminum coating. After the inspection, the secondary washing removed dust and dirt from the mirror surface. Then the mirror was placed in the vacuum chamber.

Movie 1: Primary washing (10x speed). All staff members wore protective suits. Qualified members in yellow suits and protective masks who are eligible to handle acid checked the washing process. (Credit: NAOJ)

Movie 2: Secondary washing (10x speed). (Credit: NAOJ)

Aluminum Coating

Inside the vacuum chamber, which is just big enough to accommodate the 8.3-meter primary mirror, 288 tungsten filaments pre-wetted with aluminum had been installed. When the filaments were fired (heated by an electric current running through them), the aluminum evaporated. Due to limits on the available electrical current, the filaments were fired in three groups of 96. Aluminum vapor released from the filaments created a thin film on the mirror surface. To create a homogeneous film, the process needed to be conducted in vacuum, free from disruptions by the air.

Movie 3: Firing process filmed from the chamber window (10x speed). (Credit: NAOJ)

Movie 4: The primary mirror came out of the vacuum chamber four days after the firing (10x speed). (Credit: NAOJ)

Finish and the Recovery of the Mirror Reflectivity

After the primary mirror came out of the chamber Satoshi Miyazaki, director of Subaru Telescope, inspected its finish together with engineers and scientists. The vacuum chamber is located on the base floor of the telescope dome, and washing and coating were done there. After the inspection, the mirror was lifted by a crane back to the third floor (observation floor), where the telescope is located and then attached to the telescope. The reflectivity measurements showed that just after the recoating, the mirror returned to the same values as in 2017 (Figure 3).

Figure 2: Group photo taken after the mirror coating inspection. The high resolution image is here (1.8 MB). (Credit: NAOJ)

Figure 3: Changes in the reflectivity of the primary mirror over time. The reflectivity recovered from the low value before recoating (measured on July 15, 2022) back to the initial value after the 8th coating in 2017 (measured on October 22, 2017). Detailed information about the reflectivity is available on the Observing page of the Subaru Telescope website. (Credit: NAOJ)

Movie 5: The cell with the primary mirror being lifted back to the observation floor by a crane (20x speed). A camera attached to the cell took this movie. (Credit: NAOJ)

For about two months, multiple staff members took photos and videos every day to document the work process. These will be used for reference for the next, 10th, coating.

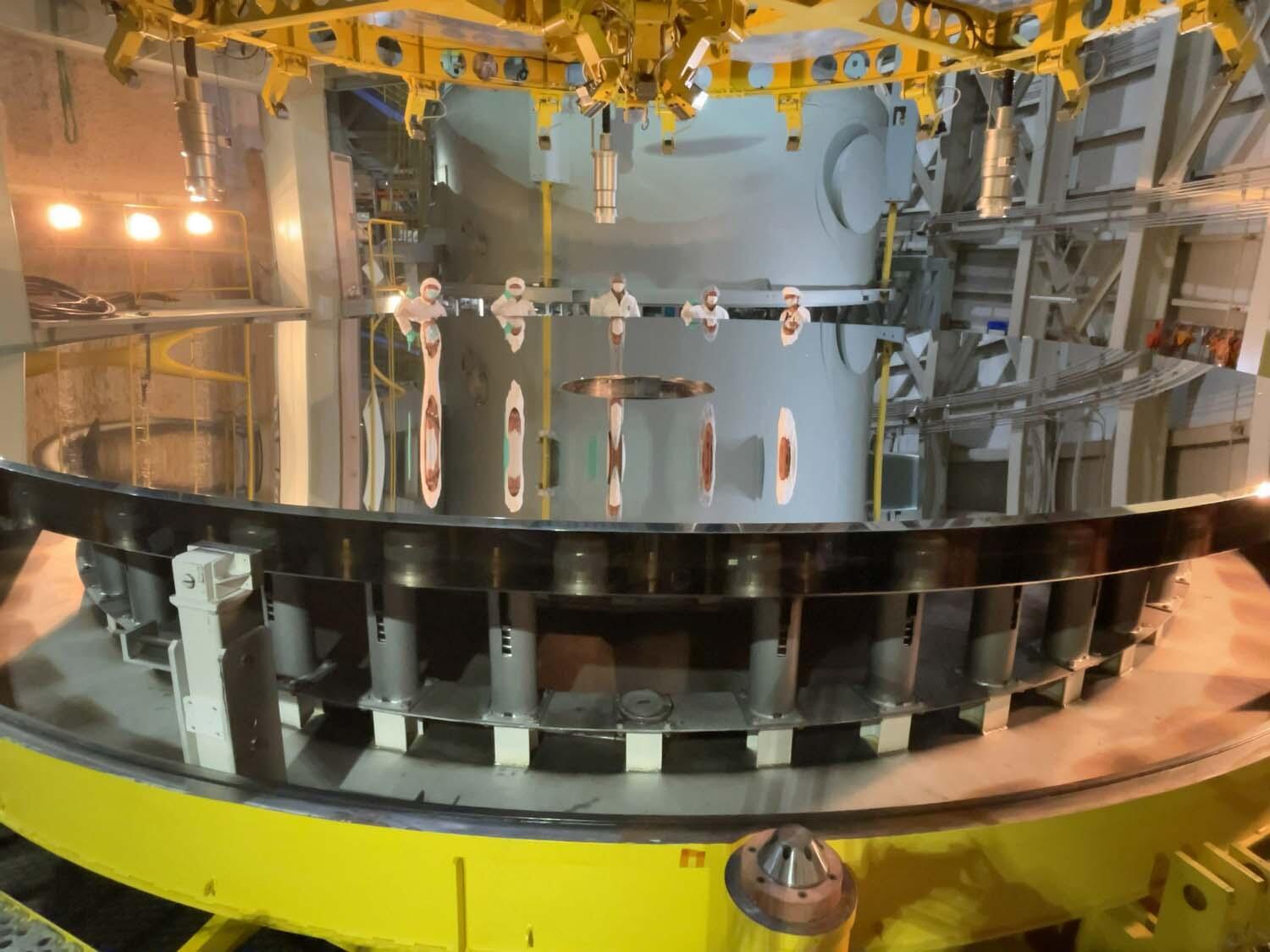

Figure 4: Group photo taken with the primary mirror cell, when it came back from the base floor after the recoating work. This photo shows the mirror cell before being mounted to the telescope, and the actuators, the robotic fingers supporting the mirror, can be seen. The high resolution image is here (1.8 MB).(Credit: NAOJ)