|

Show content only (no menu, header)

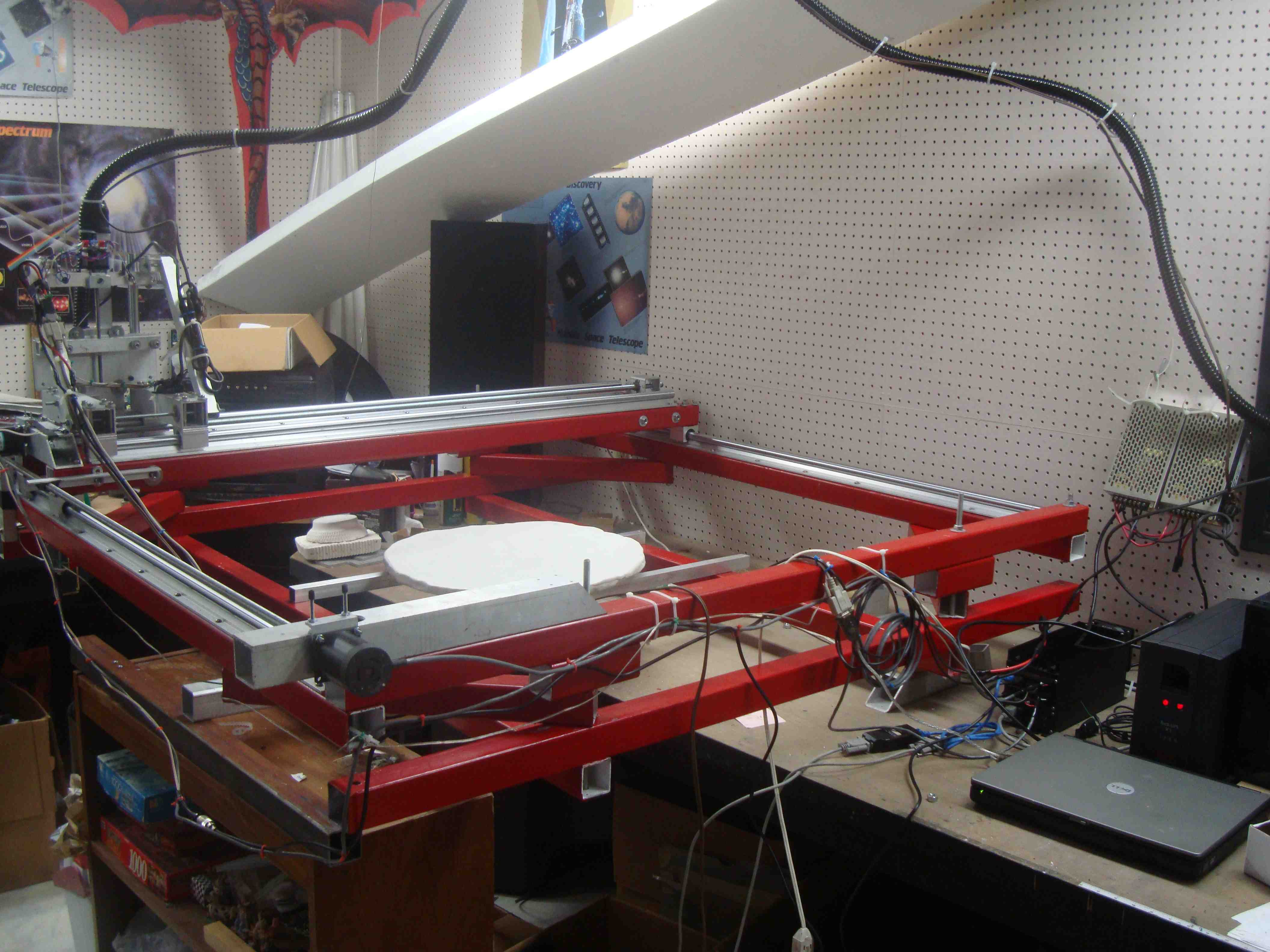

Grinding/Polishing machine

This Computer Numerically Controlled (CNC) grinding / polishing machine serves 3 purposes:

- Machining for the mold used to slump the mirror

- Fine grinding of the mirror

- Polishing of the mirror

Overview

The CNC machine can grind and polish blanks of up to 1.4m diameter. I built it out of steel stock and various mechanical components as described in this page.

|

Wide view of the ginding/polishing machine. The plastic film around the machine, and the metal hose under, prevent dust buildup during plaster mold grinding, and keep dust away for polishing.

|

|

Top view of the CNC machine.

|

|

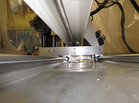

Dust evacuation duct. There is a 120VAC fan inside the duct to suck air from the top of the machine to the bottom and send it outside the building through a hole in the floor.

|

Mechanical design

|

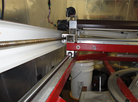

Left X axis bearing. A linear ball bearing is visible in the bottom. The ball screw, driven by a stepper motor, is used to drive the X axis. The Y axis motor and bearings are visible in the background.

|

|

A chain keeps the 2 sides of the X axis in sync.

|

|

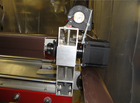

Y axis stepper motor driving the Y axis ball screw (not visible - behind the brown plastic cover).

|

|

Y axis linear ball bearings (bottom) and ball screw (top).

|

|

Z axis.

|

|

Machining tool for the wax. This tool was made by cutting a pizza cutting wheel in 4. It's a cheap way to make a large radius of curvature tool, which is ideal to shape the wax.

|

Old pictures of the machine

These pictures show an early version of the machine, with conventional screw instead of ballscrews, smaller steppers, and single side drive for the X axis.

|

Wide view of the ginding/polishing machine.

|

|

Grinding head. The black plastic pipe is for dust control, and is connected to a modified vacuum cleaner outside the building.

|

Page content last updated:

27/06/2023 06:35:52 HST

html file generated 27/06/2023 06:34:42 HST

|