|

SiC refractory concrete used to make the slumping mold. |

|

Plaster blank after the SiC mold has been separated from the plaster (side view). |

|

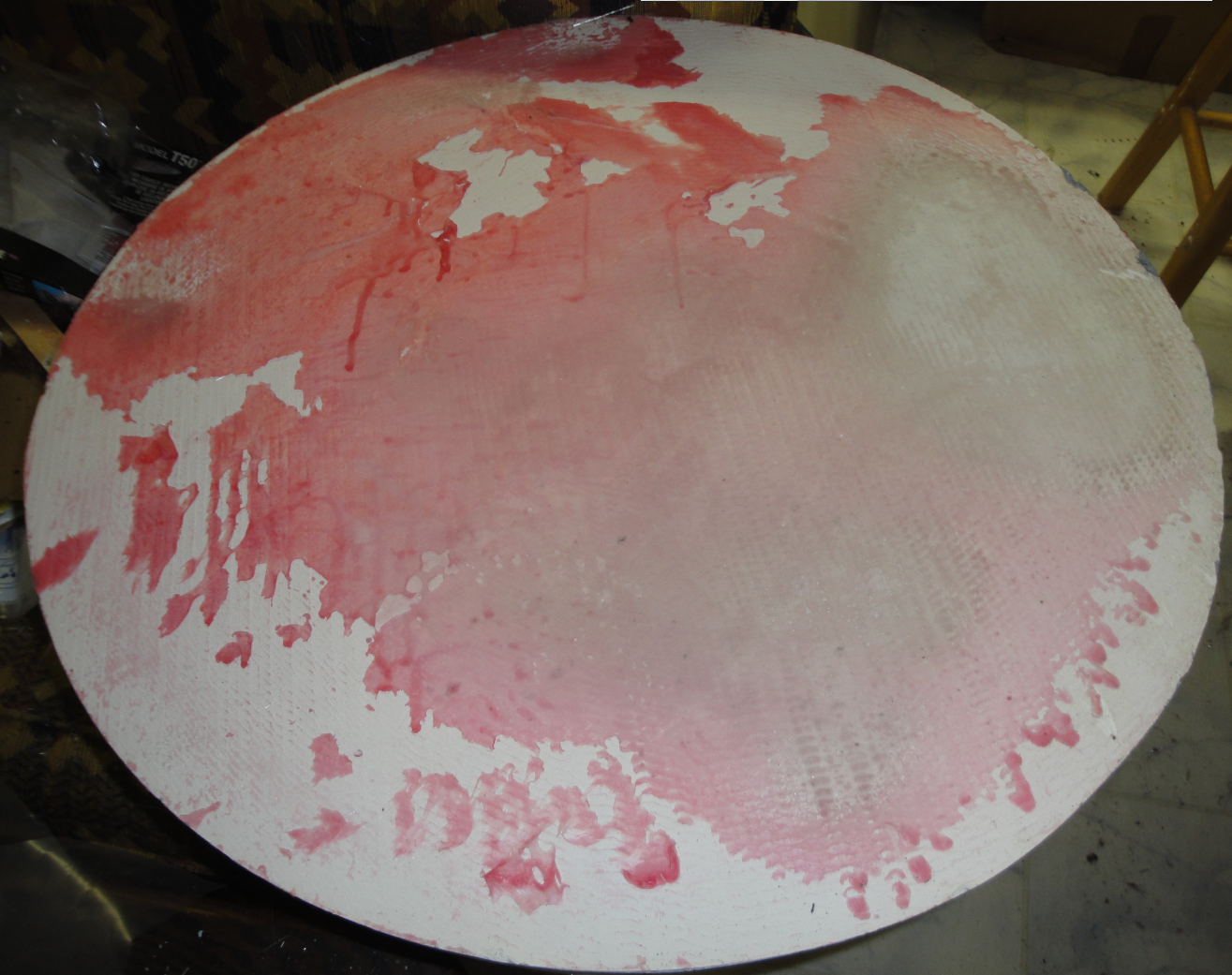

Plaster blank after the SiC mold has been separated from the plaster (front view). The red melted wax can be seen on top of the blank. |

|

SiC slumping mold inside the oven (wide view). |

|

SiC slumping mold inside the oven. |

|

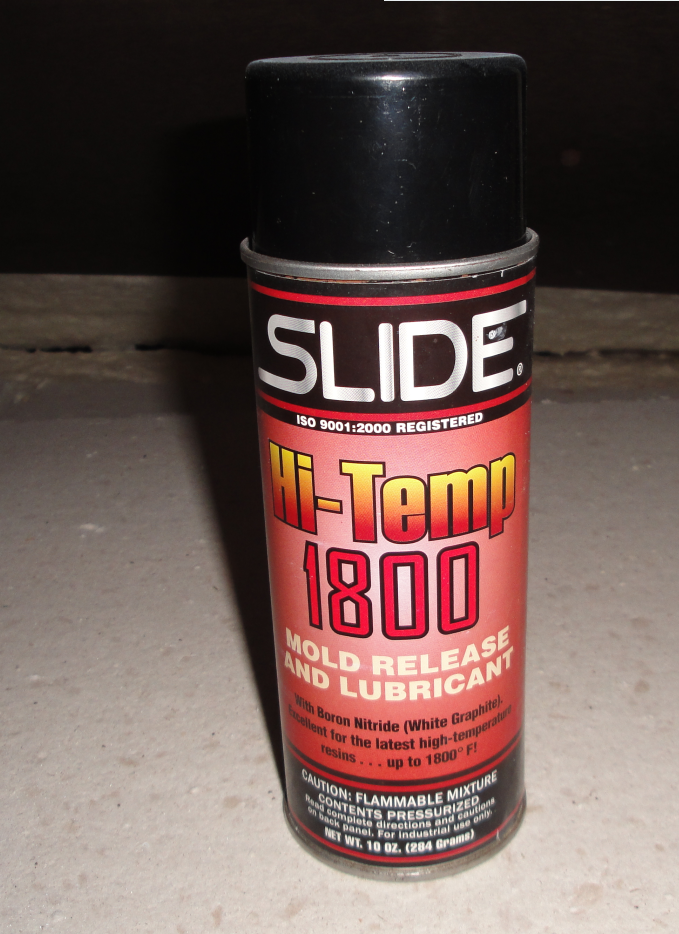

Boron Nitride is sprayed on the mold to avoid having the glass stick to the mold. |